| Place of Origin: | CHINA JIANGXI |

|---|---|

| Brand Name: | NKCHEM |

| Certification: | ISO9001:2000 |

| Model Number: | polypropylene pall ring |

| Minimum Order Quantity: | 1 cubic meter |

| Price: | $1.00 - $10.00/ cubic meter |

| Packaging Details: | Conventional packing |

| Delivery Time: | 5-8work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, L/C, D/A |

| Supply Ability: | 500 Cubic Meter/Cubic Meters per Month |

| Product Name: | Plastic Random Packing | Product Range: | Pall Ring, Raschig Ring, Tellerette Ring Etc |

|---|---|---|---|

| Classification: | Tower Packing, Column Packing, Air Scrubber Packing | Color: | White, Grey, Yellow, Transparent Etc |

| Application: | Adsorption, Stripping Service | Application Temperature: | 60-150 Cesus |

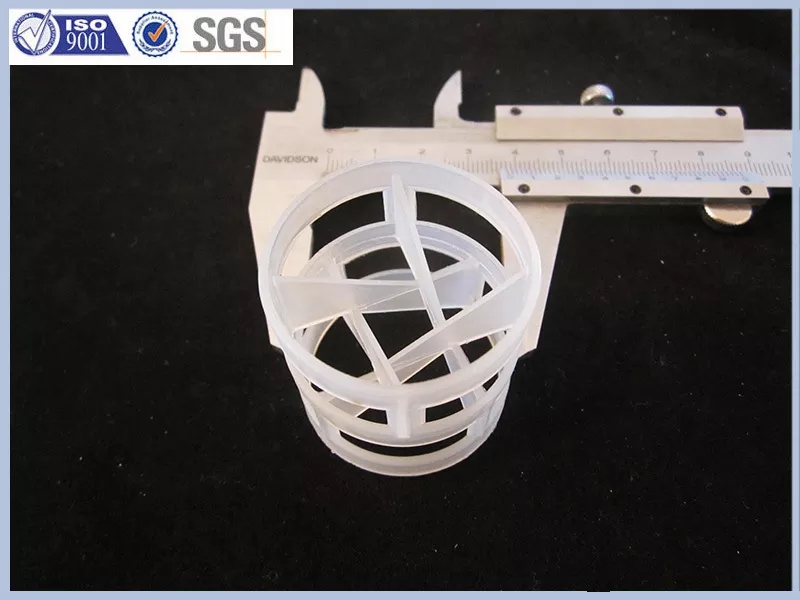

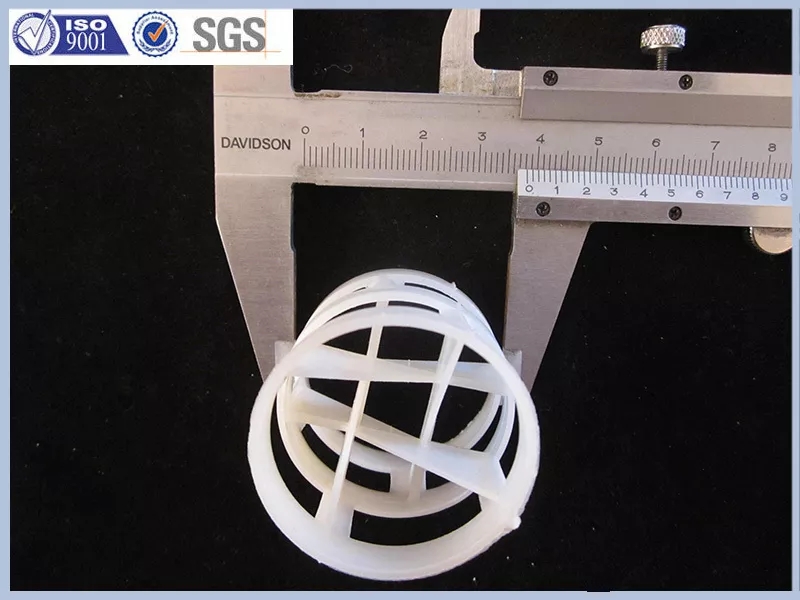

Polypropylene Pall Rings

Polypropylene Pall Rings is made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chloridized polyvinyl chloride (CPVC) and polyvinylidene fluoride (PVDF). Polypropylene Pall Rings has features such as high free volume, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on, and the application temperature in media ranges from 60to 150. For these reasons Polypropylene Pall Rings is widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc...

Polypropylene Pall Rings is a proven design that provides higher capacity and lower pressure drop than trays and other random packing.By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment,the Polypropylene Pall Rings geometry enables high gas and liquid transfer rates.The open cylinder walls and inward bent protrusion of the pall ring allow greater capacity and lower pressure drop than standard cylindrical rings.

This open ring design also maintains an even distribution and resist wall-channeling tenencies.The interior and exterior contacting surface of the pall ring provide for an effective distribution of liquids and gasses and resist plugging,fouling and nexting.

Polypropylene Pall Rings Technical Specifications

| No. | Specifications | Bulk density | Number per volume | Surface area | Void volume |

| 1 | 20*20*2 | 522 | 110000 | 267 | 0.928 |

| 2 | 25*25*2 | 423 | 56000 | 219 | 0.934 |

| 3 | 38*38*2 | 368 | 14000 | 165 | 0.946 |

| 4 | 50*50*2 | 390 | 6500 | 113.5 | 0.949 |

| 5 | 65*65*2 | 480 | 4600 | 84 | 0.948 |

| 6 | 76*76*2 | 328 | 1850 | 73 | 0.92 |

Feature:

1. High free volume

2. Low pressure drop

3. Low mass transfer unit height

4. High flooding point

5. Small specific gravity

Polypropylene Pall Rings Application:

1. Ethylene extraction columns

2. Mass transfer columns separation services

3. Carbon dioxide and hydrogen sulphide absorbers and flash tower

4. Liquid extractors

5. Carbon monoxide converters

6. Dimethyl terephthalate running column